In the realm of manufacturing, precision is paramount. The ability to create intricate, complex parts with utmost accuracy has long been a challenge, met with solutions that push the boundaries of technology. Among these solutions stands 5-axis CNC machining, a revolutionary method that transcends the limitations of traditional machining techniques. In this article, we delve into the world of 5-axis CNC machining services and explore how they unlock new potentials in manufacturing.

What is 5-Axis CNC Machining?

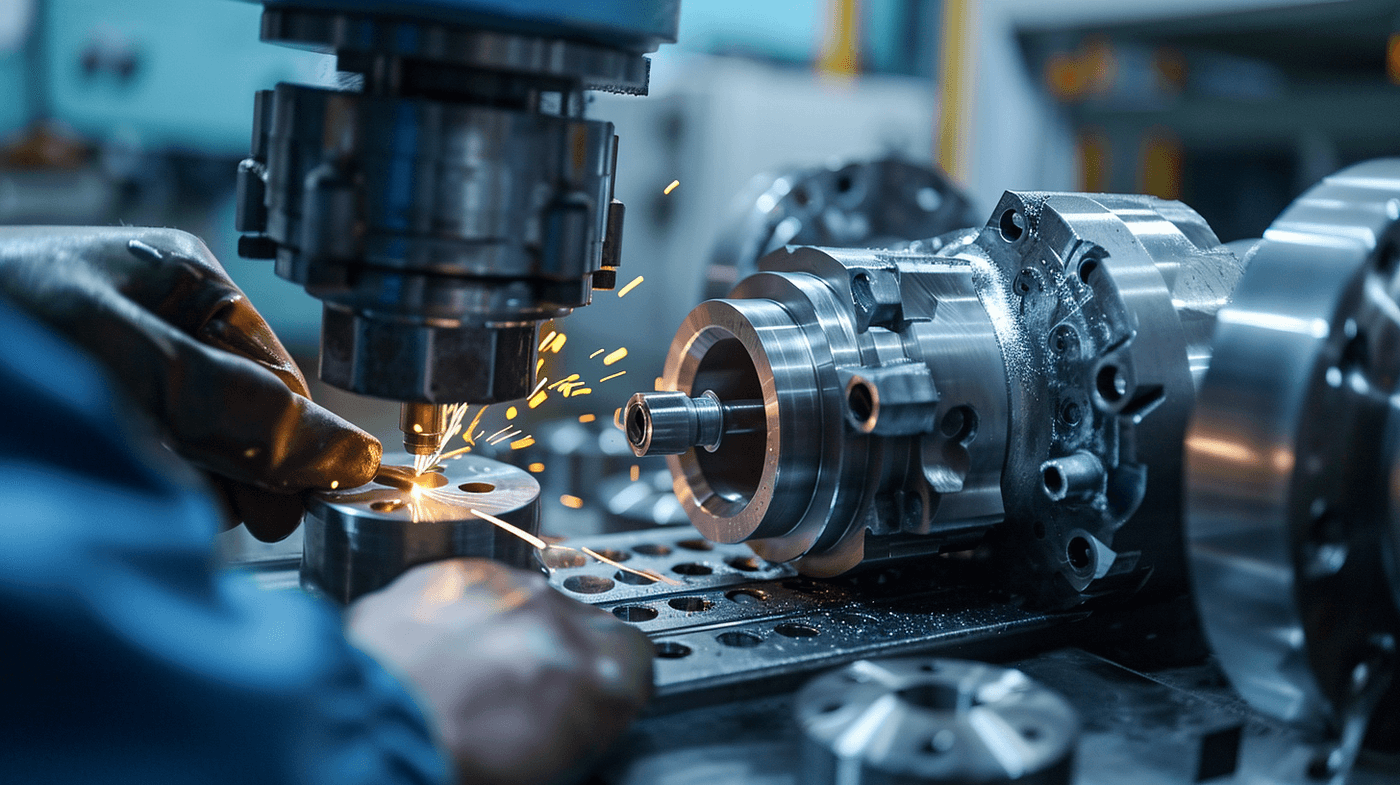

CNC (Computer Numerical Control) machining is a process that utilizes computerized controls to manipulate machine tools, producing highly precise parts from various materials. Traditional CNC machines operate on three axes – X, Y, and Z – restricting movement to linear paths. However, 5-axis CNC machining introduces two 5 axis cnc machining rotational axes, enabling a significantly broader range of motion.

Unraveling the Power of Multi-Axis Machining

The primary advantage of 5-axis CNC machining lies in its ability to access multiple sides of a workpiece without repositioning. Traditional 3-axis machines require manual intervention to adjust the part’s orientation, leading to increased setup times and decreased accuracy. In contrast, 5-axis machines can maneuver around a part from virtually any angle, reducing setup overheads and enhancing precision.

Complexity Meets Precision

One of the most compelling aspects of 5-axis CNC machining is its capacity to tackle complex geometries with unparalleled accuracy. By rotating the tool along multiple axes simultaneously, intricate shapes and contours can be machined seamlessly, eliminating the need for secondary operations. This capability opens doors to a myriad of applications across industries, from aerospace to medical devices, where intricate components are the norm rather than the exception.

Enhanced Efficiency and Reduced Costs

While the initial investment in 5-axis CNC machining may seem daunting, the long-term benefits far outweigh the costs. The ability to produce intricate parts in a single setup reduces lead times and minimizes material waste, ultimately translating to lower production costs. Additionally, the elimination of secondary operations streamlines the manufacturing process, further enhancing efficiency and throughput.

Pushing the Boundaries of Innovation

Innovation thrives on the ability to push beyond existing limitations, and 5-axis CNC machining serves as a catalyst for groundbreaking advancements. From lightweight aerospace components to patient-specific medical implants, the capabilities offered by multi-axis machining enable designers and engineers to explore new frontiers in product development. By transcending the constraints of traditional manufacturing methods, 5-axis CNC machining fosters a culture of innovation and drives progress across industries.

Precision Redefined: The Future of Manufacturing

As technology continues to evolve, so too does the landscape of manufacturing. 5-axis CNC machining represents a paradigm shift in precision engineering, offering capabilities that were once thought impossible. By harnessing the power of multi-axis machining, manufacturers can unlock new potentials, pushing the boundaries of what is achievable.

Conclusion

In the realm of manufacturing, precision is paramount, and 5-axis CNC machining stands at the forefront of precision engineering. With its ability to tackle complex geometries, enhance efficiency, and drive innovation, multi-axis machining services pave the way for a future where limitations are but a distant memory. As industries continue to evolve, embracing the capabilities of 5-axis CNC machining will be essential in unlocking new potentials and shaping the future of manufacturing.